CASE STUDY

Military Ground Radar Manufacturer Required Custom EMI Shielding Vent for Cabinet

THE CHALLENGE

A manufacturer of mobile military ground radar systems required an air vent that would provide both high air flow and EMI shielding for an electronics enclosure cabinet on a ground vehicle.

DESIGN REQUIREMENTS

- Paint must be camouflaged per MIL-DTL-64159

- Airflow, EMI shielding, and tempest weather sealing

- Highly custom gasket configurations

KEY CUSTOMER REQUIREMENTS

- High air flow

- Excellent EMI shielding

- Color matching to customer chassis

- High temp., humidity, and salt/corrosion

- Environmental and weather sealing

CONCLUSION

Parker Chomerics designed a custom vent with additional EMI shielding and weather sealing gaskets for a mobile ground radar unit. Our in-house test services engineers put this design through a variety of performance tests including, temperature, humidity, salt fog/corrosion, and shielding.

The vent assembly passed both shielding tests, as well as the customer’s visual inspections of what occurred during tests such as humidity and salt fog/corrosion. Overall, this was a successful qualification procedure.

THE SOLUTION

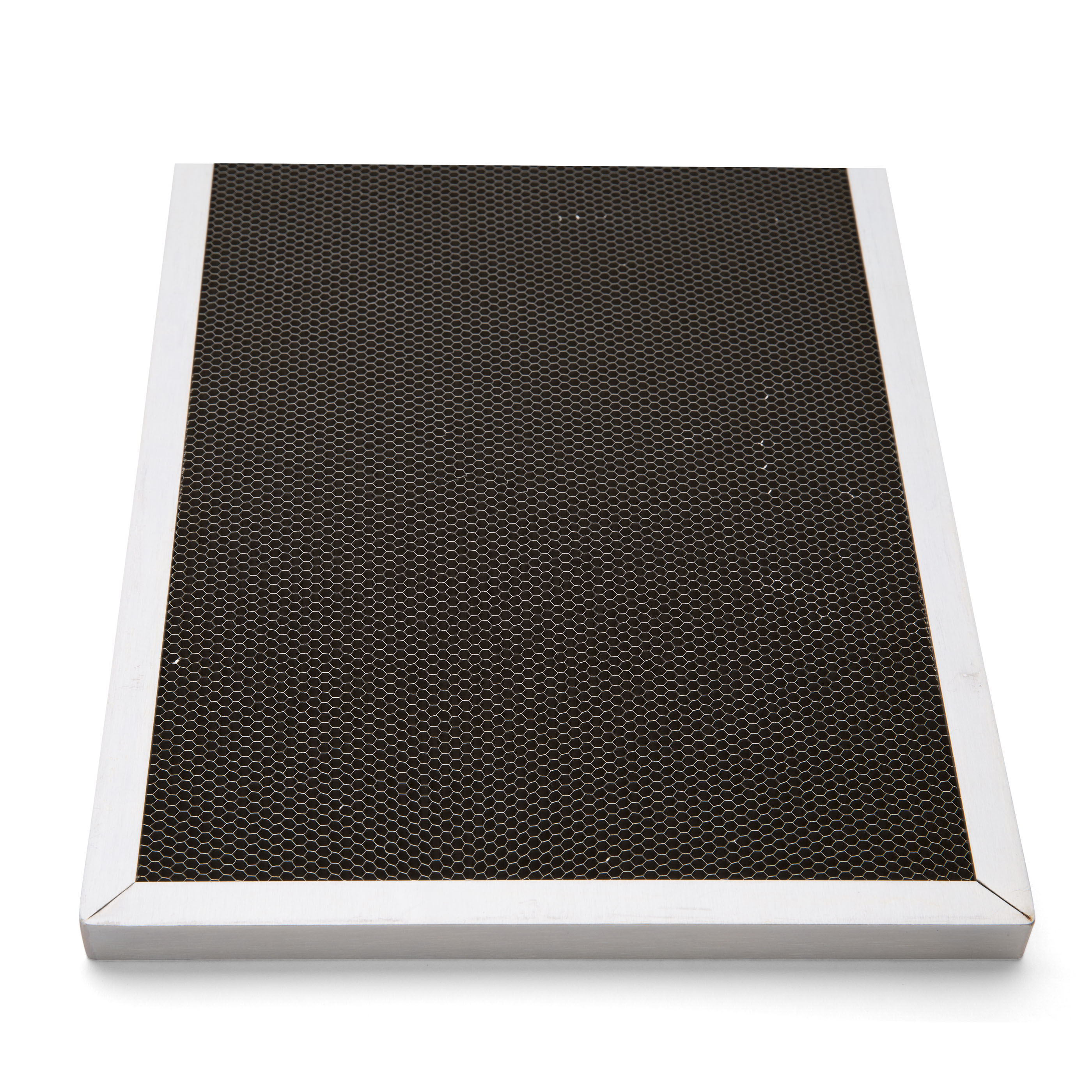

Parker Chomerics designed a custom air vent featuring a tin/e. nickel plated, single layer 1/8in cell aluminum honeycomb. The single layer allowed for maximum airflow, with the plating providing high EMI shielding performance.

A CHO-SEAL® co-extruded EMI gasket was fitted into a groove in the vent frame. This gasket features a single, homogenous strip with one half being conductive and the other half providing weather sealing. Testing was performed and the assembly exceeded customer’s shielding and sealing requirements.

Electrically Conductive Elastomer Gaskets

Parker Chomerics electrically conductive elastomer gaskets are the superior choice for corrosion resistance, environmental sealing, and cost-effective EMI shielding. Available as molded sheets or parts, allowing for greater part complexity and detail but sometimes at a higher cost; or extruded into strips and either offered as cord stock at length or spliced (fused) to form a continuous seal. Learn More.

We’re constantly innovating in our drive to create the most advanced clean energy solutions.

Empowering Your Business on a Global Scale

Parker Chomerics’ manufacturing operations span the globe, allowing us to serve you locally no matter where you are. We understand your unique needs and provide personalized solutions that cater to your specific requirements.

Can't find what you're looking for? Talk to one of our experts.