INDUSTRY

AUTOMOTIVE

PRODUCT USED

EMI SHIELDING AND THERMAL INTERFACE MATERIAL INTEGRATED ASSEMBLY

CASE STUDY

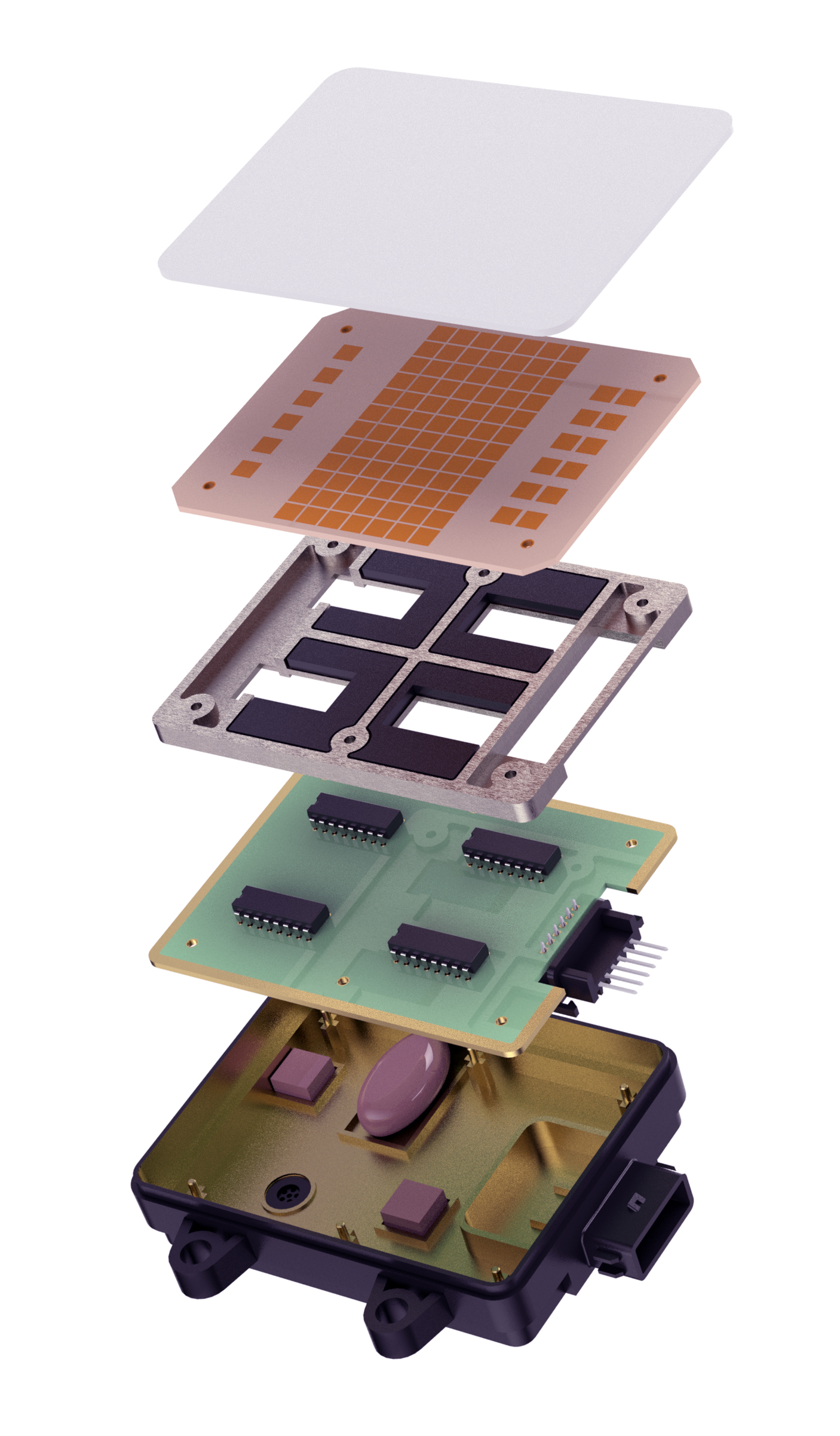

Automotive 77 GHz Integrated Radar Module Assembly

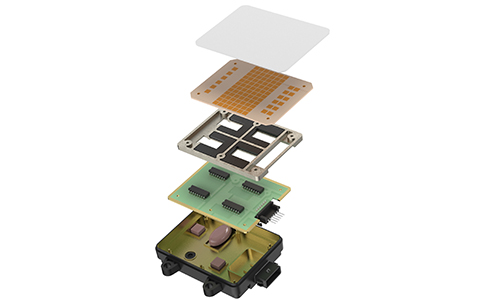

Parker Chomerics helped a global automotive supplier design and assemble a 77 GHz ADAS radar sensor housing with EMI shielding and thermal management materials supplied as a single, fully integrated assembly.

CUSTOMER CHALLENGE

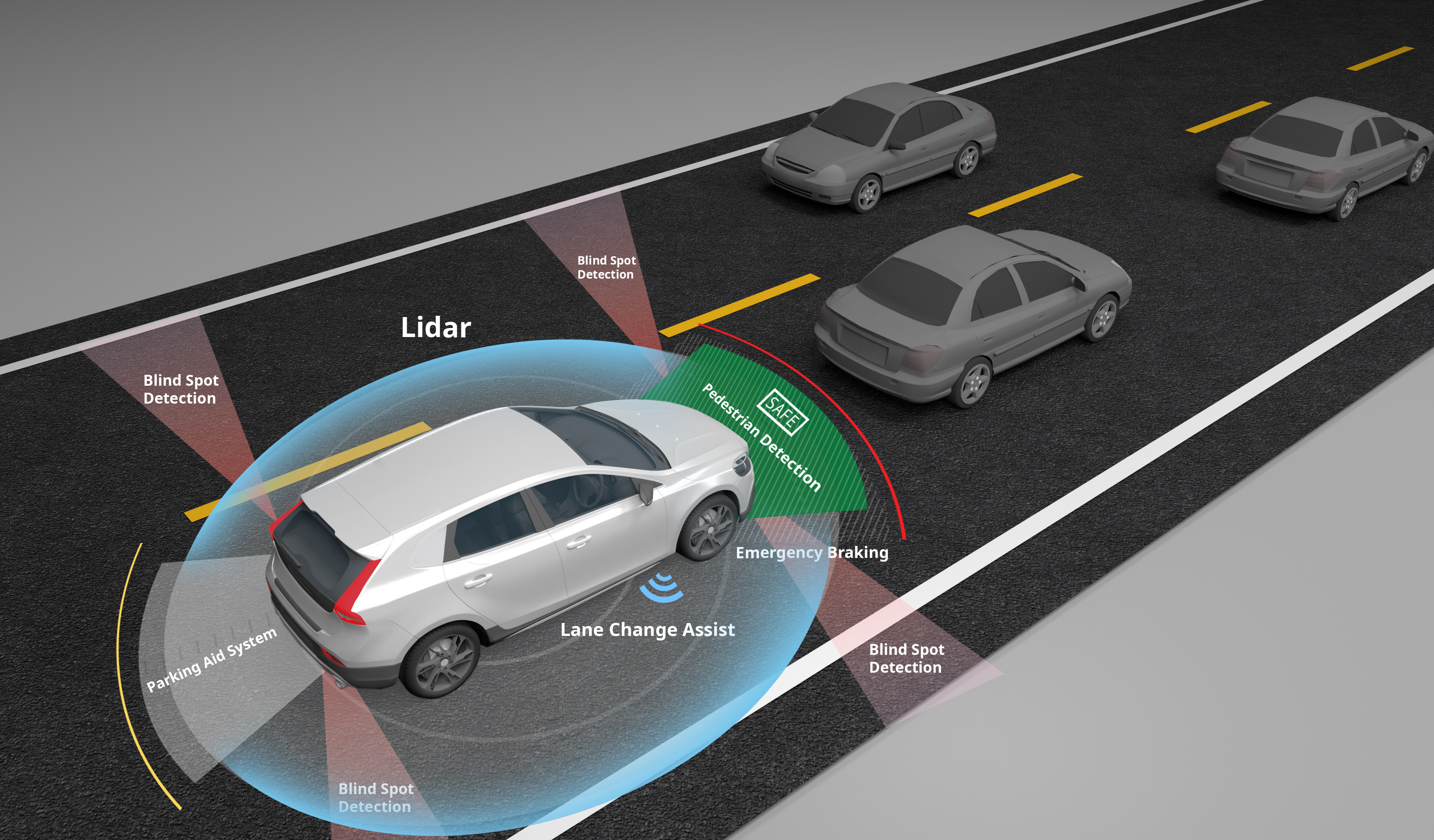

As technology in vehicles continues to rely more on advanced driver-assistance systems (ADAS), many automotive suppliers are quickly developing improvements in applications such as automotive radar sensors that are part of total solutions which will meet stringent governmental safety requirements.

Due to the width of available frequencies, many automotive radar technologies have moved from 24 GHz to 77 GHz. This higher frequency can achieve up to 20x better performance in range resolution and accuracy.

The range resolution of a 77 GHz system can be 40 mm versus 750 mm for 24 GHz radar, which allows for better detection of multiple objects that are close together. But an increase in frequency brings more EMI shielding and thermal interface material technology, so automotive suppliers look for a partner like Parker Chomerics, with our experienced application engineers to help develop new technology for these high performing applications.

Ready to get started? Contact us now.

DESIGN REQUIREMENTS

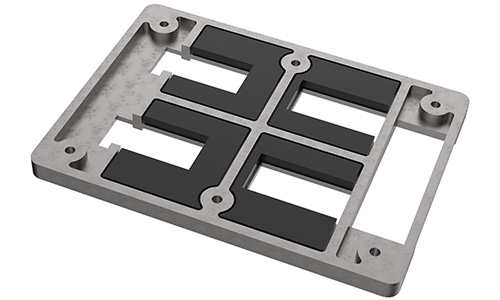

Radar module supplied as a single full integrated assembly solution.

Thermal management material with a bulk thermal conductivity of >3.0 W/m-K.

Microwave absorber pad affixed onto one side of the shield for isolated absorption within the assembly.

Radome cover molded in a plastic capable of laser welding to the plastic housing.

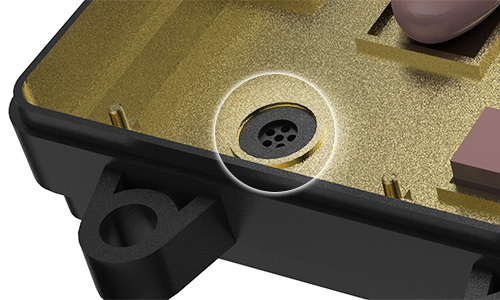

Breather membrane valve to release moisture and pressure within the housing.

SOLUTION

Parker Chomerics mechanical and application engineers, together with the customer’s engineering team, worked to design a model of the radar sensor housing, the RF shield and the radome to meet the customer’s stringent requirements.

It was determined that the housing could be either molded from Parker Chomerics PREMIER electrically conductive plastic, or, as in this case, traditional thermoplastic with an added electrically conductive coating on the inside of the housing.

The housing assembly design featured EMI shielding and thermal interface materials, an RF absorber, and a radome cover material suitable for laser welding.

During the design process, a finite element analysis (FEA) simulation was conducted to predict the reacting force of the EMI gasket around the 6-pin connector, the EMI gasket around the RF shield during installation into the housing, and the reacting force of the dispensable thermal interface material (TIM) during and after its installation.

The engineering team had to ensure that the targeted dispense location of the TIM would not cause deformation and/or damage to the PCB/IC during and after assembly.

CONCLUSION

Parker Chomerics engineers developed an intergraded solution assembly consisting of a traditional thermoplastic housing, coated with Parker Chomerics CHO-SHIELD 2056 silver-plated copper EMI shielding paint. For effective heat dissipation away from the radar's PCB, THERM-A-GAP GEL 30 dispensable gel and THERM-A-GAP 580 gap filler pads were the best overall solution for the radar sensor assembly. Parker Chomerics CHOFORM 5528 form-in-place EMI shielding gasket provided effective attenuation around the connector pin.

The combination of these materials met the extensive testing and trials by both Parker Chomerics direct customer and their end customer’s requirements.

THERM-A-GAP GEL 30

THERM-A-GAP GEL 30 is part of the Parker Chomerics family of fully cured, one component, silicone-based, dispensable thermal interface materials. With a 3.0 W/m-K thermal conductivity, it is designed for high performance heat transfer from electronics components to cooling features and meant to be used across industries and applications. Learn more.

Solutions for ADAS

Advanced Driver Assistance System (ADAS) modules and infotainment panels have led the way in terms of advancement of electronic systems within passenger vehicles. Learn more about Parker Chomerics solutions for ADAS applications.

We’re constantly innovating in our drive to create the most advanced clean energy solutions.

Empowering Your Business on a Global Scale

Parker Chomerics’ manufacturing operations span the globe, allowing us to serve you locally no matter where you are. We understand your unique needs and provide personalized solutions that cater to your specific requirements.

Can't find what you're looking for? Talk to one of our experts.