High Performance Thermal Interface Materials

With performance you can count on, Parker Chomerics will help protect your investment, now and in the future.

Thermal Gap Filler Pads or Thermal Gels?

Deciding between the thermal interface material types of gap filler pads, also called thermal gap fillers, and dispensable compounds such as thermal putties and thermal gels can be challenging. Our experts break it down so you can understand which type of thermal interface material is best for your application.

THERM-A-GAP™ GEL 20

Product Features:

- High viscosity thermal gel

- Consistent flow rate from batch to batch

Expanded Reliability Testing:

- 200 hrs at 200ºC

- Thermal Shock Testing – GMW 3172

- Larger Gap Vibration Testing 0.5-2.5mm (GMW 3172 and ETSI)

Sample Applications:

- Automotive engine control modules

- Advanced driver assistance systems (ADAS)

THERM-A-GAP™ GEL 40NS

Product Features:

- “NS” - Non-Silicone thermal gel (Urethane binder)

- Fully cured, one component material

- No silicone

- 125ºC maximum operating temperature range

Sample Applications:

- Data storage devices (Solid State Drives - SSDs)

- Automotive sensors/radars/camera modules

- Silicone-free devices or facilities

- Optical/Fiber optic connectors and housings)

THERM-A-GAP™ GEL 60HF

Product Features:

- "HF” - High Flow rate – 80 g/min (0.100” opening at 90 psi)

- Two color options – Grey and Black

- Can be stenciled

Sample Applications:

- High volume applications

- Consumer devices (mobile phones, laptops)

- Telecommunications equipment

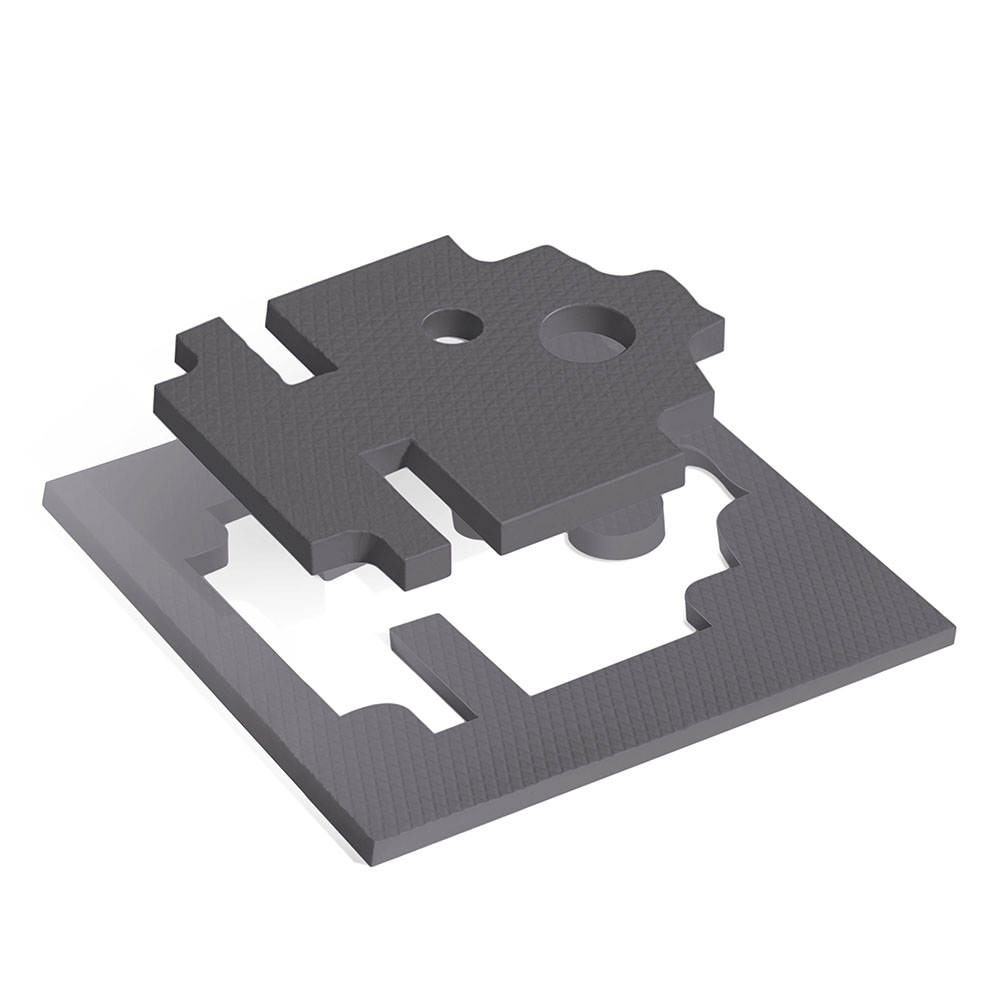

THERM-A-GAP™ PAD 70TP

Product Features:

- Very low compression force

- “Putty-like” properties

- Static, one-time assembly due to permanent deformation

- Option for carrier in middle of material

Sample Applications:

- Telecommunications equipment

- Defense electronics

- Industrial applications

THERM-A-GAP™ PAD 80

Product Features:

- High thermal conductivity: 8.3 W/mK

- Available as thin as 0.020” (0.5 mm)

- Low hardness for low compression force

Sample Applications:

- All industries

- Defense/Aerospace

- Telecommunications infrastructure

- Consumer Electronics

- Automotive

PROVEN PERFORMANCE

Engineering thermal solutions for electronic devices.

We continue to advance technologies to bring new and enhanced capabilities and efficiencies.

Non-Silicone Dispensable Thermal Gel for Automotive Infotainment and Camera Modules

Advanced Driver Assistance System (ADAS) modules and infotainment panels have led the way in terms of advancement of electronic systems within passenger vehicles. As cars and trucks continue to modernize, advanced driver options are becoming standard in nearly every class of vehicle. While “electrification” and “EV” buzzwords have taken center stage in conversations about vehicle electronics, drivers of all vehicle types as well as passengers and pedestrians are the beneficiaries of advanced safety, navigation, and entertainment systems.

Protect Equipment with a High-Performing Gap Filler Pad

New from Parker Chomerics is the THERM-A-GAP™ PAD 70TP Thermally Conductive Gap Filler Pad. This ultra-soft, ultra-conformable, high-performance product provides a very low hardness (15 Shore 00) solution with 7.0W/m-K thermal conductivity. THERM‐A‐GAP PAD 70TP is designed to provide effective heat transfer between electronic components and their associated cooling features such as heat sinks.

Non-Silicone Dispensable Thermal Interface Material for SSD Modules

While by no means a new technology, Solid State Drives (SSDs) have shown a marked increase in adoption over Hard Disk Drives (HDDs) at both the consumer and enterprise scale over the last decade. With the advantages of faster speeds, no moving parts, long-term reliability, and quieter operation, SSDs have become the current standard as well as the future for data storage.