CASE STUDY

Non-Silicone Dispensable Thermal Gel for Automotive Infotainment and Camera Modules

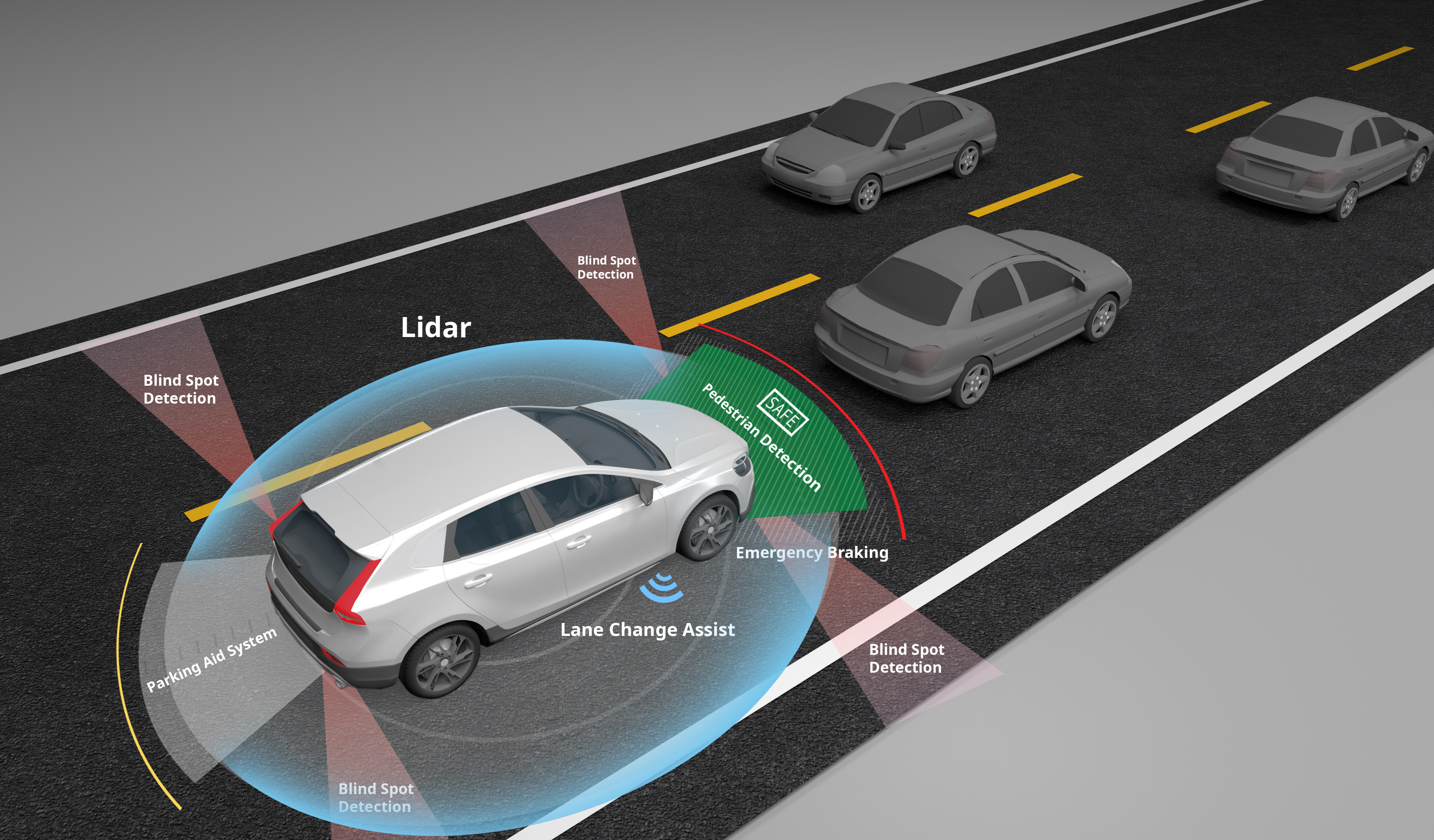

Advanced Driver Assistance System (ADAS) modules and infotainment panels have led the way in terms of advancement of electronic systems within passenger vehicles. As cars and trucks continue to modernize, advanced driver options are becoming standard in nearly every class of vehicle. While “electrification” and “EV” buzzwords have taken center stage in conversations about vehicle electronics, drivers of all vehicle types as well as passengers and pedestrians are the beneficiaries of advanced safety, navigation, and entertainment systems. The overarching term sometimes used to summarize these electronics systems is Audio Video Navigation and Telematics or AVNT.

Design Challenges for Infotainment and Camera Module Engineers

Automotive electronics designers and engineers have been working with component suppliers to push the boundaries of material properties used to maintain long term reliability of these AVNT and Infotainment systems. The basis for long term reliability has been higher performance processors and chips, leading to secondary design concerns. Electronic modules have to be electrically shielded to prevent interference from nearby modules and also cooled to prevent overheating, a leading cause of electronic device failure. In the case of safety features, device failure is not an option.

Secondary concerns for integrated electronic devices also surround the limitations around the use of cameras and vision systems. A VAST majority of thermal interface materials utilize a silicone binder with a thermal conductive filler, often ceramic, graphite, or passivated metallic materials. However, issues arise due to the incompatibility of optical modules and silicone binder systems.

Silicone is an ideal binder material for thermal interface materials due to: large operating temperature range, high maximum use temperature, ease of use, low cost, excellent mixing and material integration properties, and chemical/harsh fluid resistance. However, there are some drawbacks that can be critical in certain applications. Silicone thermal materials have a high composition percentage of silicone oil, an undesired material or extractable that can sometimes be expelled from the thermal gap pad or gel under conditions of high compression force. At high temperatures, this oil can exhibit volatility properties and start to evaporate or migrate within assemblies as well. This volatility is sometimes referred to as outgassing and is quantified by the ASTM E595 test procedure. This migration may be a concern from an aesthetic perspective where silicone oil can pool or flow across board components. While it is non-toxic and electrically insulating so there is little concern of shorting electrical junctions, the oil can also be a nuisance as it is difficult to clean. Additionally, silicone oil that makes its way onto lenses, sensors, and precision optical measurement or communication equipment can impact the effectiveness of the signal transmission and the image quality.

NOTE: It is important to note that not all mission critical or safety applications must avoid silicones. As mentioned earlier, silicone oil tends to migrate or exhibit volatility only when exposed to high temperatures or compression forces. When in controlled settings, silicone-based thermal materials are still the desired solution.

Designers who work with fiber optic equipment or camera modules are often forced to find alternatives to silicone materials or at the very least select those materials with the lowest measured volatility rating. ADAS and AVNT systems use cameras, high precision radars, and smart switches to provide inputs into vehicle feedback and instantaneous process controls. These systems must function without error or delay 100% of the time. Silicone oil migration leading to signal transmission delays is simply not acceptable when the lives or drivers, passengers, and pedestrians are at stake.

Parker Chomerics was approached by a global leader in AVNT technology with requirements for a next generation, high performance thermal interface material that would be utilized across several platforms.

Key Customer Requirements

- Non-silicone binder

- Can be integrated into high volume, automated assembly processes

- Thermal Conductivity ≥ 3.5 W/mK

- Pre-cured material or no secondary curing process required

- Globally available – Manufacture in Asia, Europe, and North America

Based on the given customer requirements, Parker Chomerics developed THERM-A-GAP GEL 40NS. Building on the previous success of THERM-A-GAP GEL 25NS, GEL 40NS is based on the same urethane binder mechanism and utilizes a high conductivity blend of ceramic particles for very low thermal impedance. With a thermal conductivity of 4.0 W/mK, GEL 40NS exceeded customer thermal expectations. As with other thermal gels and liquid dispensed gap fillers, it is easily integrated into automated assembly processes and packaged into a variety of cartridge sizes from 10 cc syringes up to 1-gallon pails but also has an improved flow rate allowing for faster dispensing and thus shorter assembly times.

CONCLUSION

Parker Chomerics global process and product development teams worked with leaders in the automotive electronics industry to develop a state-of-the-art non-silicone thermal interface material and gap filler that would be an integral part in the long-term reliability of advanced safety features across various vehicle makes and models. THERM-A-GAP GEL 40NS is the next generation of material where silicone use is limited or restricted. While developed for high reliability automotive applications, there is no telling what other industries can benefit from a 4.0 W/mK, one component, fully cured, dispensable, urethane-based thermal interface material and gap filler.

THERM-A-GAP GEL 40NS

Solutions for ADAS

Advanced Driver Assistance System (ADAS) modules and infotainment panels have led the way in terms of advancement of electronic systems within passenger vehicles. Learn more about Parker Chomerics solutions for ADAS applications.

We’re constantly innovating in our drive to create the most advanced clean energy solutions.

2023 Thermal Interface Material Innovations

Over the last year, Parker Chomerics has developed new, state of the art thermal interface materials, or TIMs, for use across industries and applications. These novel products continue to expand the portfolio of high performance, high reliability thermal gap pads and dispensable thermal gels.

Can't find what you're looking for? Talk to one of our experts.