CASE STUDY

Thermal Interface Materials for EV/Hybrid DC/DC Power Converter Modules

A global manufacturer of power control modules for EVs needed a fully cured dispensable thermal gel with excellent heat dissipation for their EV DC/DC converter control module.

Thermal Interface Material Challenges for DC/DC Power Control Modules

As the demand increases for electric vehicles (EVs) and hybrid electric vehicles (HEVs) worldwide, manufacturers must also cope with the increase in 12V or 24V accessories that traditionally have been powered by an alternator. In EVs and HEVs, this alternator is replaced with a DC/DC converter which can transfer the energy between the power source and on board accessories.

The amount of heat dissipated is dependent on the output load and converter efficiency. The control and evacuation of this heat is called thermal management. Prudent thermal management will result in long term reliable operation and allow maximum power utilization in a minimum amount of space.

Ready to get started? Contact us now.

Thermal Interface Material Design Requirements for DC/DC Power Modules

- Thermal interface material is easy to dispense by robotic systems

- Lower deflection force

- Small assembly gap

- Good heat transfer from components to heat sink

- Verified performance of vertical gap slump application

- Good dielectric strength to avoid breakdowns

Key Customer Requirements for Materials

- Converter structure has to be reliable and lightweight

- High efficiency, low electromagnetic interference and low current/voltage ripple

- Heat that is generated from the converter must be adequately dissipated through the housing

SOLUTION

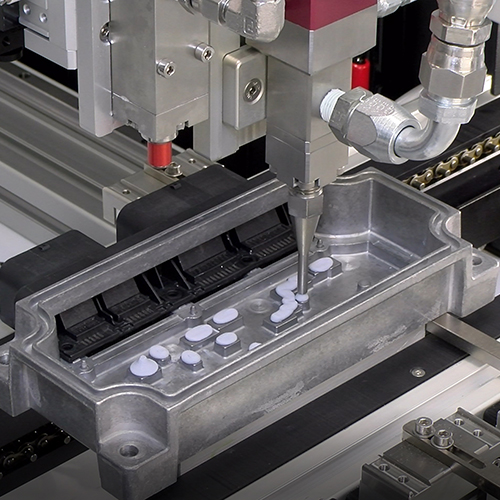

The recommended solution for this automotive component manufacturer was to dispense Parker Chomerics THERM-A-GAP® GEL 30 in various patterns onto the heatsink.

A 300cc cartridge solution was implemented and will eventually convert to high volume manufacturing using a 1 gallon pump unit (1 GPU) and valve dispensing system.

This gave the customer a lower deflection force, excellent thermal performance, all in a solution that was easier to dispense with an overall competitive total value to thermal pads or thermal grease.

CONCLUSION

Parker Chomerics THERM-A-GAP® GEL 30 fit the needs and the specifications of the automotive component manufacturer’s requirements. High volume dispensed thermal interface materials are ideal for automotive applications where cost, time, and efficiency are of the utmost importance

START NOW, CONTACT US

Interested in Parker Chomerics Parker Chomerics THERM-A-GAP GEL 30? Click below to get a quote!

Sign up for the Parker Chomerics monthly newsletter and keep up to date on everything Chomerics.

By signing up, you'll be the first to know:

- New product releases

- Updated support documentation and articles

- Existing product notifications

- The latest white papers, videos, and much more!

Parker Hannifin Chomerics Division

77 Dragon Ct., Woburn, MA 01801

781-935-4850