Engineered Materials Group

Engineered Polymer Systems Division

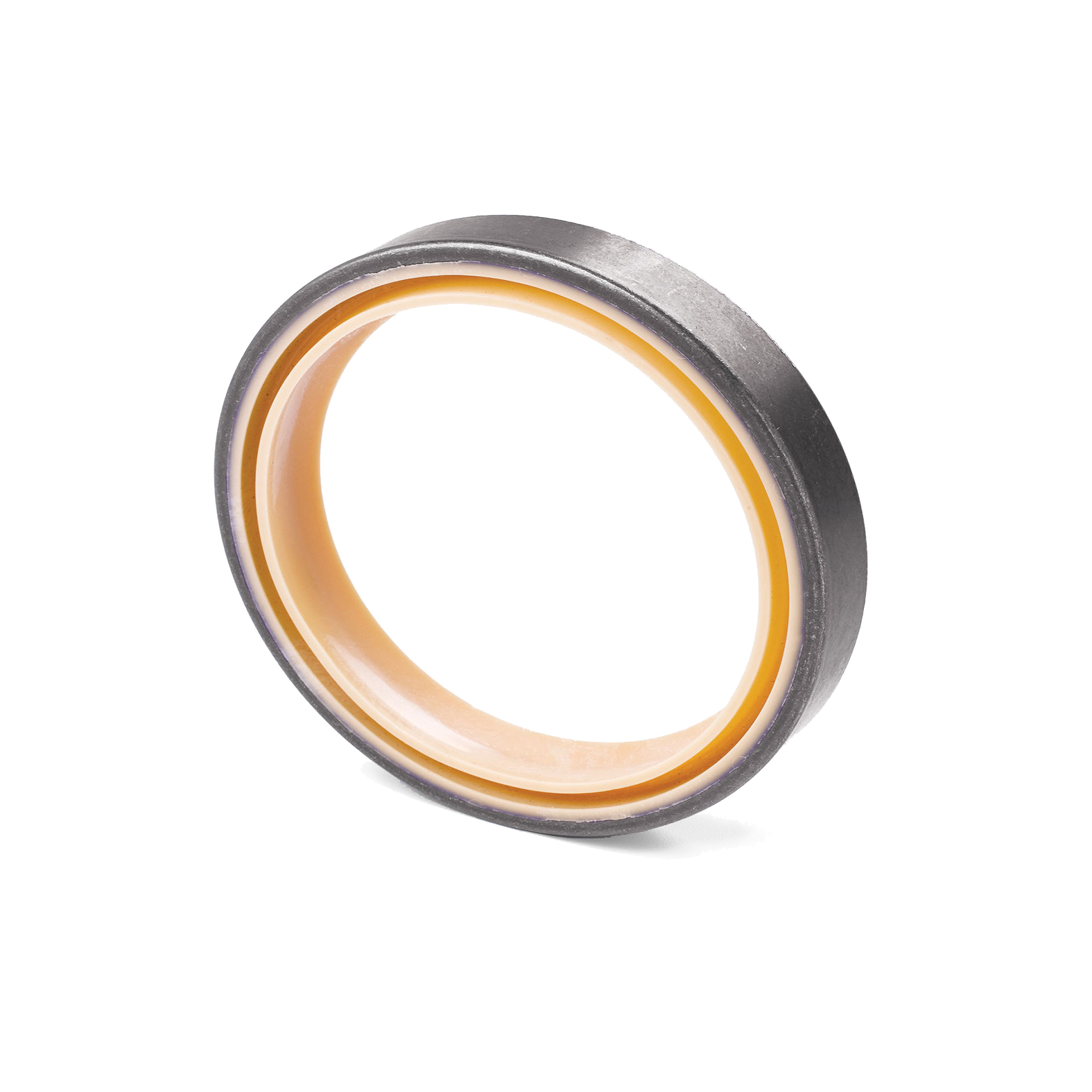

Resilon® Polyurethane Seals Products

for Oil & Gas Frac Pumps

Keeping well completion hydraulic fracturing operations going becomes difficult when wear and tear causes leakage or seal failure. Taking frac pump equipment offline to replace fluid end consumable seals and valves is unproductive and costly.

To last for all the stages in a frac job, seals need to be tough. That's where the physical properties of Parker's wear-resistant Resilon® polyurethane are well suited. Its PPDI-based polymer chemistry gives it:

- Extreme abrasion resistance for long wear

- Resilience and resistant to compression set so it retains high sealing force

- High temperature compatibility in continuous operation temperatures of 230°F (excursion temperatures up to 275°F)

- Ability to withstand frictional heat generated by rapid cycling

- High pressure capability up to 15,000 psi

FEATURED RESILON® SEAL PRODUCTS FOR FRAC PUMPS

FOR RELIABLE PERFORMANCE AND IMPROVED EFFICIENCY IN WELL COMPLETIONS

Advantages of Resilon polyurethane materials for positive displacement pump seals over all other commercially available TPU sealing materials includes:

- Excellent abrasion resistance for increased seal life

- Resilient with excellent rebound for faster reaction to rapid changes in pressure

- Toughness for long wearing performance

- Resistance to compression set and extrusion at higher pressures

- Thermal suitability for use in sealing applications that experience high frictional heat from high temperature and high pressure operating conditions

Durable Resilon Formulations

Resilon® Polyurethane Physical Properties

| Resilon® Material Code | P4300 | P4301 | P4312 |

|---|---|---|---|

| Hardness (Durometer), Shore | 90 A |

90 A | 60 D |

| Modulus @ 100% elongation, psi | 1674 | 1850 | 2979 |

| Ultimate tensile strength, psi | 8021 | 7188 | 7085 |

| Ultimate elongation, % | 638 | 548 | 554 |

| Specific gravity | 1.17 | 1.18 | 1.16 |

| Temp Range, Min to Max, (°F) | -65 to 275 | -35 to 275 | -65 to 275 |

Note: Values listed are typical values and should not be used as specification limits.

Read the Blog

Parker's Resilon® polyurethane sealing products can improve the bottom line of well completion operations by reducing frequency of consumable seal component replacement in mud and frac pumps. Seals wear out, but they need to last an entire well completion cycle.

Read the blog to learn:

- How the characteristics of Resilon polyurethane seal material hold up in a variety of frac pump sealing products to resist wear from abrasive fluid proppant, high pressure, and vibrating motion generated by high frequency pulsating pressurization

- Why operators and service technicians alike recognize the performance and value of the "tan colored Parker seal material" that identifies it as the durable, long-life sealing solution for frac pumps

Support & Technical Information

RESILON INFORMATION AND MUD PUMP SEAL BROCHURES

- Overview: High Performance Seals for Frac and Mud Pump, Brochure EPS5235

- Resilon® High Performance Polyurethanes from Parker, [URL]

- Resilon® Dual Purpose Pony Rod Seal, Brochure EPS5238

- Well Service Packing for Oil & Gas Hydraulic Fracturing, Brochure EPS5266

- HGP Profile, Extended Life Frac and Mud Pump Suction or Discharge Cover Seal, Brochure EPS5239

CONTACT US

Fill out the form and one of our engineering associates will contact you to discuss solutions for your application.

©2021 Parker Hannifin Corporation

Engineered Polymer Systems Division

Ph: 800 233 3900