Engineered Materials Group

Composite Sealing Systems Division

High Performance Metal Seals

for Gas Turbine Engine Applications

Parker Hannifin’s CSS Division designs and manufactures resilient metal seals for aerospace and power generation gas turbine engine applications where extreme temperature and pressure conditions prohibit the use of elastomeric and polymeric materials.

Our design team works with new product integration engineers at top aerospace and power gen companies to ensure success with metal seals in meeting critical sealing and performance objectives including ease of installation, improved fuel efficiency and optimal air-flow management.

FEATURED HIGH PERFORMANCE METAL SEALS

FOR RELIABLE PERFORMANCE AND IMPROVED FUEL EFFICIENCY IN GAS TURBINES FOR AEROSPACE AND POWERGEN APPLICATIONS

Metal Seal Design & Manufacture

Our expertise in base metals, custom coatings, specialty metals, designing for unique envelopes, improved safety, error-proof placement and installation only begins to describe the wealth of engineering, validation and manufacturing solutions we provide customers.

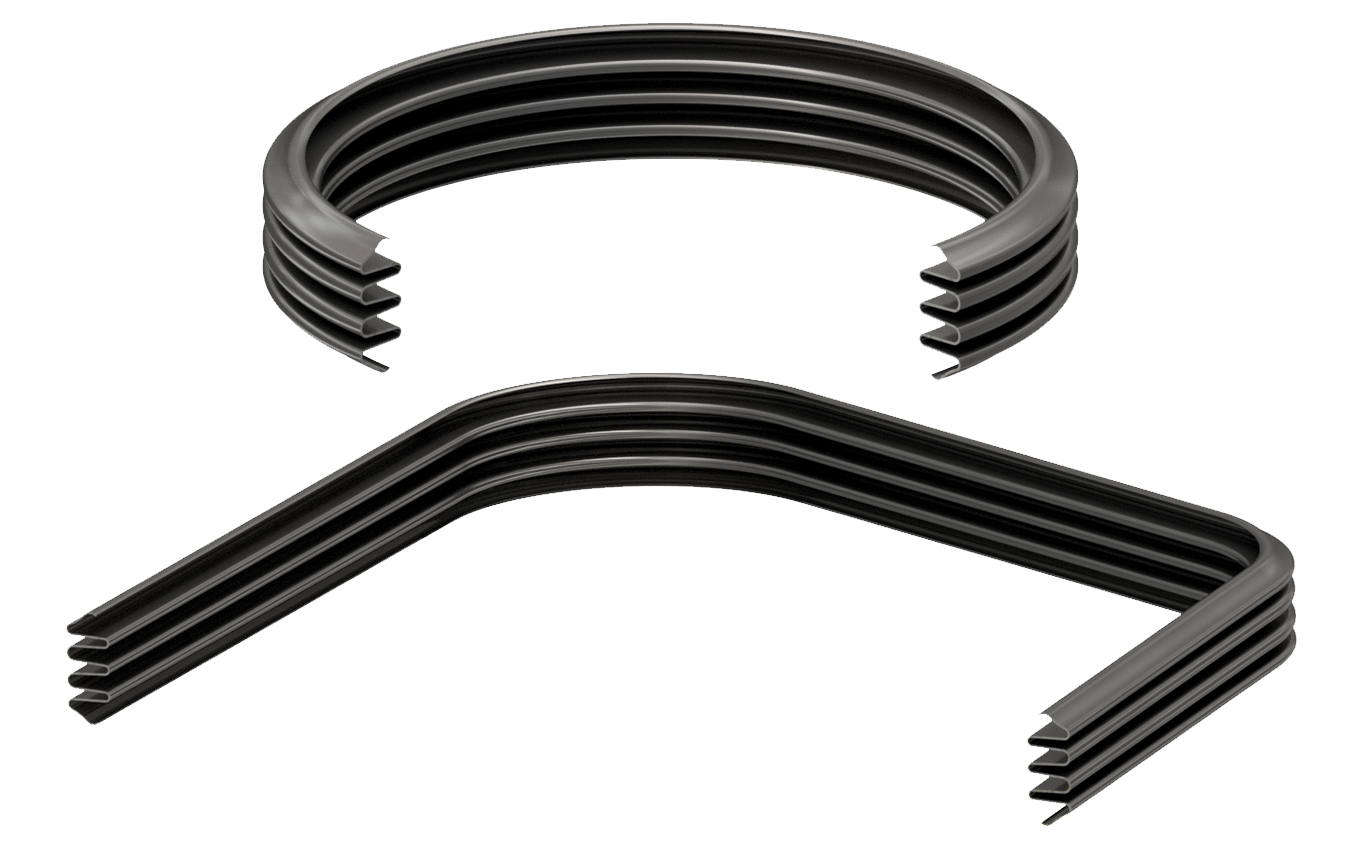

Parker's standard product offering and custom engineered solutions include:

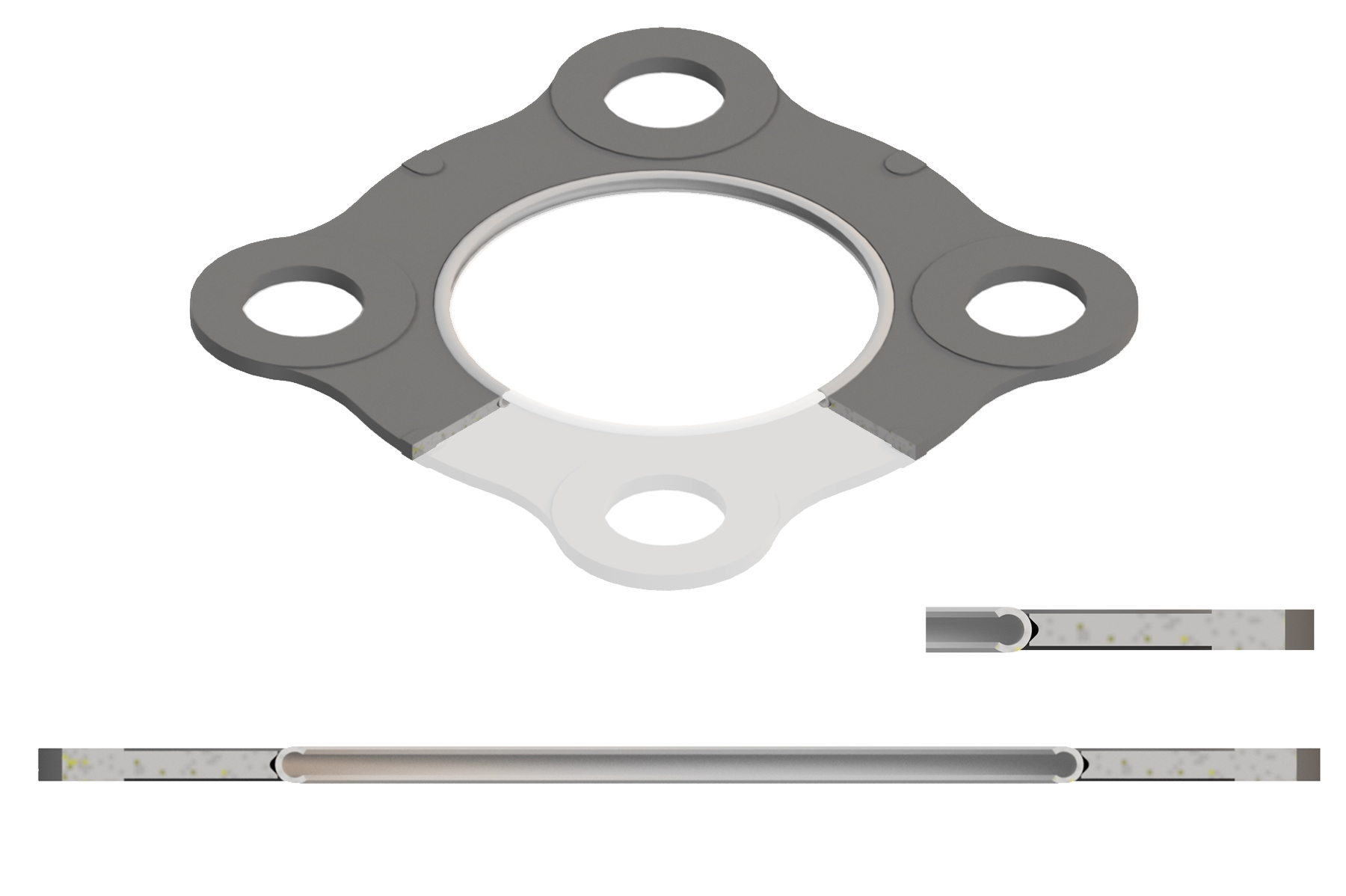

- Metal Seal Size Range: From 0.350" to 60" diameter full hoop; Larger if segmented; Smaller depending on cross-section

- Temperature Range: Cryogenic to 1450°F

- Pressure Range: Vacuum to 50,000+ psi

- Wide range of materials to ensure compatibility with wide range of fluids

- Corrosion resistant material and durable designs to ensure seals will outlast hardware

- Pre-compression features that help overcome installation challenges

- TriCom® coating that extends life by creating an anti-wear and oxidation-resistant system

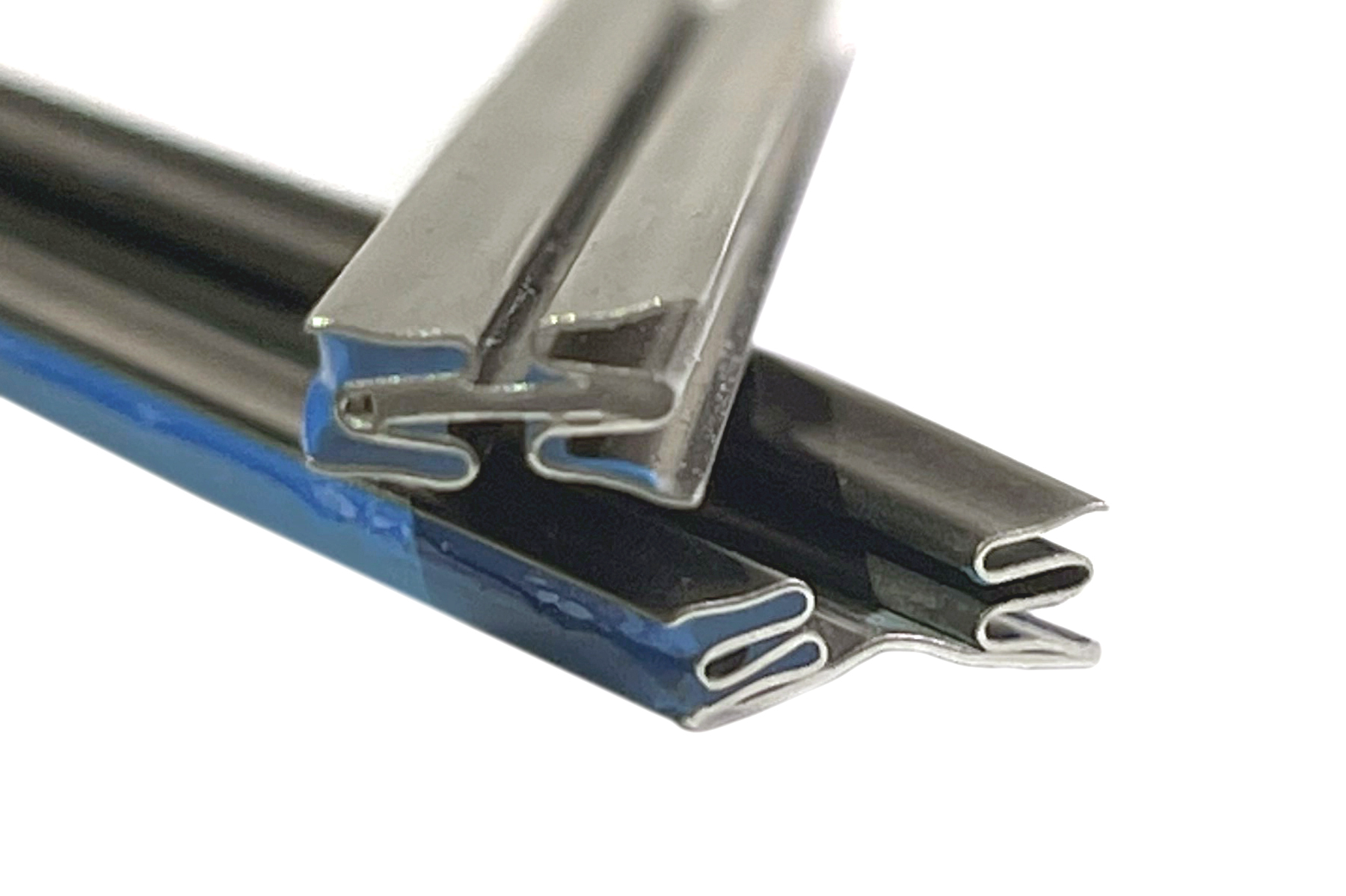

Platings and Coatings

Platings and coatings create a ductile, low hardness outer surface layer that ensures optimum sealing despite mating surface imperfection.

Coatings such as TriCom® and TriCom-HT™, are electro-deposited coatings that create an anti-wear and oxidation resistant system that significantly reduces seal and mating surface wear caused by thermal expansion and vibrational movement.

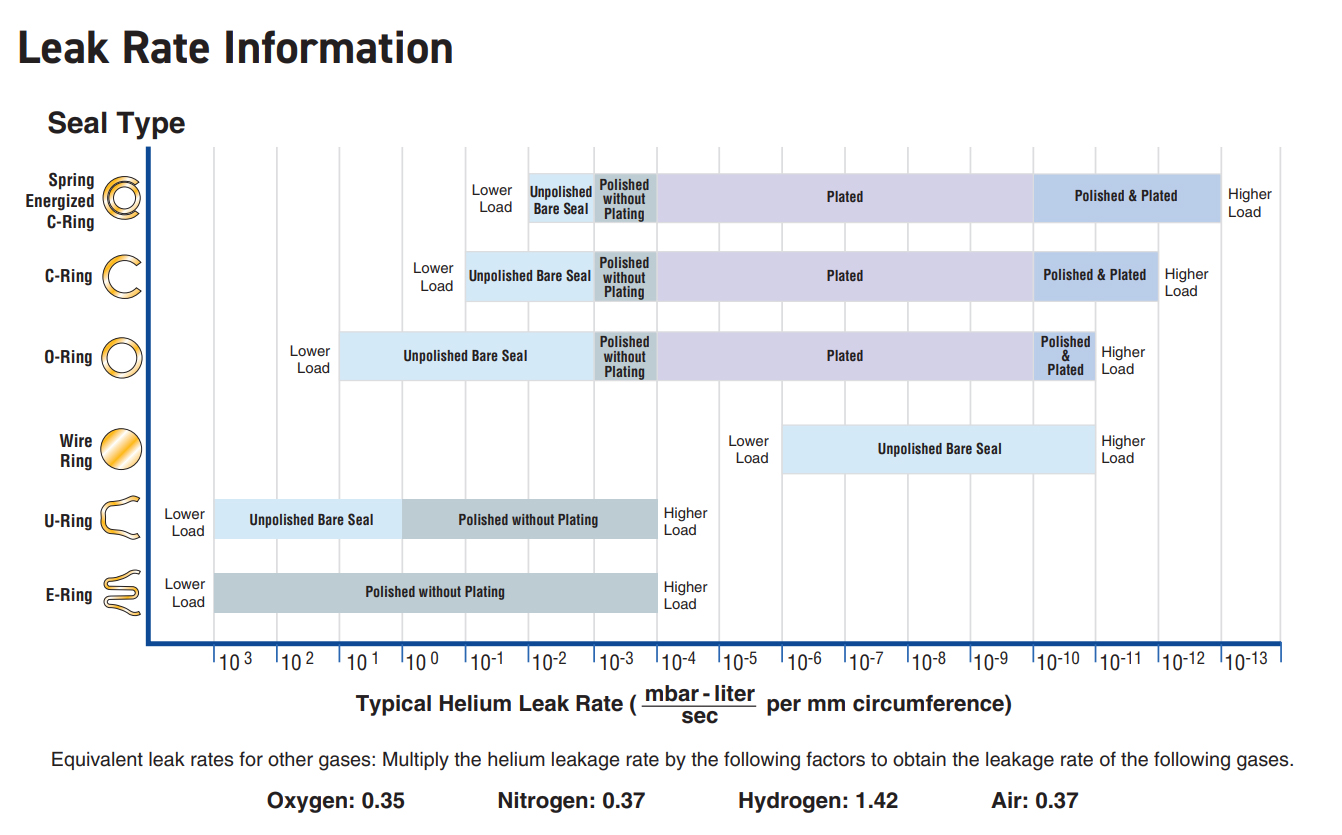

The graph above shows typical ranges of leakage rates that may be expected with various types of seals. The widths of the horizontal bars indicate the spread of leakage values that may be expected depending on the specific plating selection and surface condition.

Originally hosted May 5, 2021

Key Takeaways:

- Learn about design features of metal seal profiles which make them ideal for various gas turbine aerospace and power gen applications.

- Learn how base metals are enhanced with custom coatings and/or platings to overcome sealing challenges

- Learn about design options for resilient metal seals to overcome issues with thermal expansion and movement

- Discover how Parker enhances new product integration design, qualification, and validation processes with advanced technology.

Read the Article

Making dependable sealing systems for safety-critical applications goes beyond excellence in design and manufacturing. It also means a deep commitment to understanding our customers’ challenges and developing fluid containment solutions specifically tailored to overcome them.

In this article we highlight four solutions we provided to aerospace and power generation customers in response to metal sealing challenges they encountered in gas turbine applications.

METAL SEAL DESIGN GUIDE, BROCHURES & CATALOGS

Contact us to discuss metal sealing solutions for your application.

Fill out the form below and one of our engineering associates will contact you.

©2021 Parker Hannifin Corporation

Engineered Materials Group

Composite Sealing Systems Division

Ph: 203 239 3341

FOLLOW US